Data courtesy1

Industrial 3D printing applications

Data courtesy2

Robotics and End of arm tooling (EOAT)

See how HP 3D Printing with HP Multi Jet Fusion helps these companies reinvent the design and manufacturing of custom robotics and grippers.

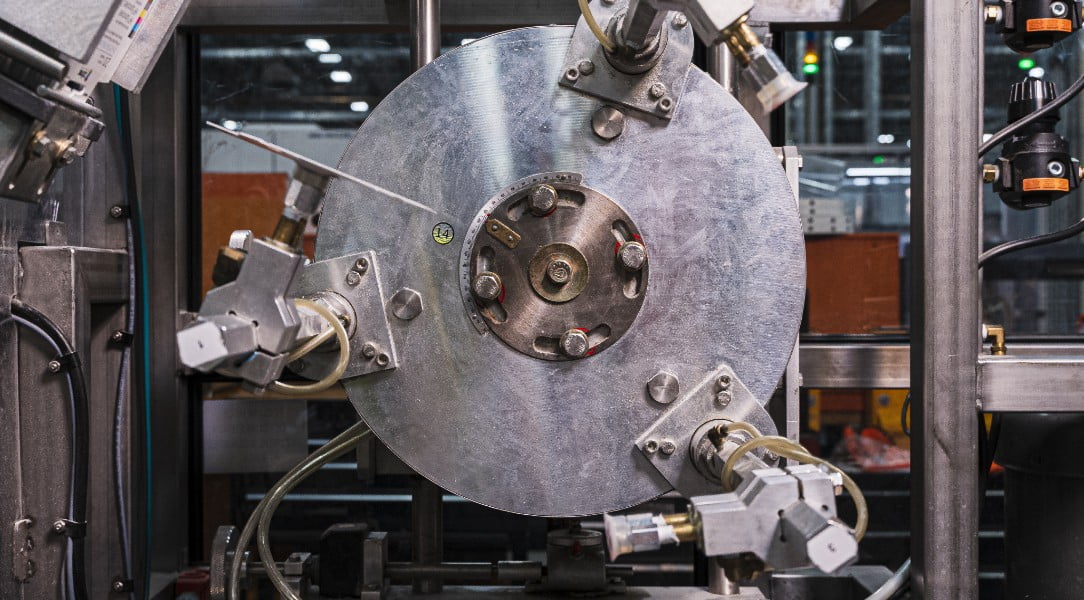

Machinery, equipment, and manufacturing lines

Complement CNC machining, injection molding, and other traditional manufacturing methods with strong, customized, lightweight 3D printed parts.

More industrial 3D printing applications

How is 3D printing driving change in the manufacturing sector?

Paul Miller, Principal Analyst at Forrester Research, offers his perspective on the benefits and adoption status of additive manufacturing.

Request your free part sample10

Experience HP 3D Printing mechanical properties produced with engineering-grade thermoplastic materials.

Watch how industrial 3D printing unlocks new possibilities for these companies

L’Oreal

L’Oreal

L’Oreal turned to HP Multi Jet Fusion 3D printing technology to quickly respond to shifts in its manufacturing processes and production lines.

Data courtesy ⁷

Schneider

Schneider

Schneider sees HP Metal Jet as a viable option for serial part manufacturing, planning to leverage the technology across its business.

Fast Radius

Fast Radius

HP 3D Printing and Fast Radius help Bastian Solutions with industrial production.

Data courtesy ⁸

FICEP S3

FICEP S3

FICEP S3 accelerates the overall speed of production and improves productivity.

Data courtesy ⁹

Find a parts supplier specialized in industrial 3D printing

FAQs about industrial 3D printing:

1. What is industrial 3D printing?

Industrial 3D printing refers to the use of 3D printers for rapid, volume part production with manufacturing predictability, reliability, and productivity. These printers are equipped to produce quality parts at high speeds, providing a faster return on investment. While the initial cost of acquiring an industrial 3D printer may be higher, their higher-end construction, like the HP Jet Fusion 5200 Industrial 3D Printer, and user-friendly interfaces make them reliable and durable for repeated use.

In contrast to entry-level 3D printers, the yield combined with throughput, productivity, and cost per part that you would get from one of these manufacturing-ready industrial 3D printers is a world apart. If you're interested, you can learn more about industrial 3D printers and their costs.

2. How much is HP 3D Jet Fusion 5200 and 4200?

Industrial 3D printers are versatile, durable, and reliable and they typically require an operator, so the investment is better suited for businesses that are certain about the role 3D printing plays in their supply chain.

It’s worth noting that the price of these printers may be calculated as a solution consisting of different elements that the 3D printer vendor recommends for your specific needs. These elements may include 3D printer hardware, post-processing equipment, services, and other tools that support your manufacturing workflow.

To get more detailed cost information, please contact an HP 3D Printing expert.

3. How much does an industrial 3D printer cost?

3D printers are available in various sizes and ranges, from small, low-cost home machines to large-scale industrial printers. While some require a limited setup and are easy to operate, others can be extremely technical and demanding. Additionally, some printers are suitable for producing individual items, while others are designed for industrial quantities, or specific materials like plastics or metals.

To know how much you can expect to pay for a 3D printer, the best approach is to fully understand your needs and specify them when requesting a quote. This way, you can get a price that is tailored to your unique requirements.

Connect with us for your industrial 3D printing needs or read this article to gain a better understanding of the cost of 3D printing machines and to get an idea of what you might need to pay based on your specific requirements.

4. Who are industrial 3D printer companies?

Industrial 3D printer companies are manufacturing firms that support OEMs in producing prototypes and final parts for various industries. Their expertise in areas such as application development, part design, printing, post-processing, and quality control makes them a competitive option for outsourcing the production of functional prototypes and high-mix, low-volume serial manufacturing.

Specifically, HP Digital Manufacturing Partners are industrial 3D printer companies evaluated and qualified by HP based on their end-to-end 3D printing service capabilities for mass production, manufacturing, and quality processes. These companies can help accelerate a business’ digital transformation with 3D-printed parts, enabling rapid innovation, faster time-to-market, distributed manufacturing, and a leaner supply chain.

5. Industrial use of 3D printers?

3D printing is rapidly becoming a key technology enabler for efficient design and production in the industrial sector. Additive manufacturing offers many industrial 3D printing applications that can optimize performance, cut lead times, and reduce costs. Some of these applications include the manufacture of machinery and industrial equipment, production-line components, robots, end-of-arm-tooling (EOAT), molds, manufacturing aids, tooling, jigs, and fixtures.

6. Why 3D printing?

3D printing, also known as additive manufacturing, enables you to produce geometrically complex objects, shapes, and textures. It often uses less material than traditional manufacturing methods and allows the production of items that were simply not possible to produce economically with traditional manufacturing.

If you’re new to 3D printing technology, it might be useful to compare this technology to traditional manufacturing methods such as:

- Subtractive Manufacturing (SM) is the controlled removal of material, like milling, for example.

- Formative Manufacturing (FM) takes a material, usually plastic, and reshapes it to create a final product.

Compare these to 3D printing or additive manufacturing, which involves adding material in layers to create the final product.

Want to deep dive more? Read the article What is 3D printing and what is additive manufacturing.

7. How fast can industrial 3D printers print?

HP Jet Fusion industrial 3D printers take between 9 to 20 hours for a full build depending on print mode, 3D printer, and material.

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Gimatic, APCC, Fast Radius & Bastian Solutions, Seb’Automatisme, SigmaDesign, IAM 3D Hub and Ficep S3.

- Data courtesy of IAM3D Hub

- Data courtesy of CNC Würfel

- Data courtesy of Gimatic srl

- Data courtesy of Bowman International

- Data courtesy of SigmaDesign

- Data courtesy of l’ Oreal

- Data courtesy of Fast Radius and Bastian Solutions

- Data courtesy of Ficep S3

- 3D Part Sample promo is only available in UK, Ireland, Netherlands, Belgium, Luxembourg, Sweden, Norway, Finland, Denmark, Poland, Czech Republic and Israel.

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.