Interested in other articles?

Interested in other articles?

What is rapid manufacturing?

Rapid manufacturing refers to a collection of different processes that enable the agile, flexible and efficient production of short-run and customized parts, in addition to bridge production, which creates a seamless transition from rapid prototyping to mass manufacturing.

Many traditional manufacturing methods require tooling, which is typically expensive and time-consuming to produce. With injection molding, for example, a mold can cost more than $30,000 and take 8 weeks or more to develop. In contrast, rapid manufacturing solutions utilize computer-aided design (CAD) and other digital technology to eliminate the need for tooling, enabling faster parts with less setup and lower capital risk.

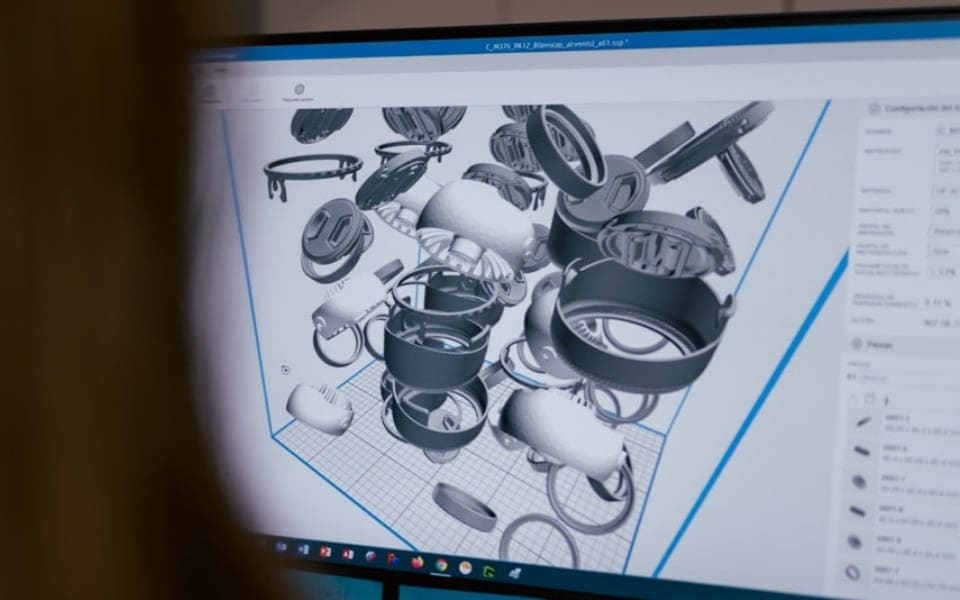

Rapid manufacturing encompasses a wide gamut of technologies including additive manufacturing (aka 3D Printing), CNC machining, and laser and water-jet cutting, among others. They all utilize digital files and offer software automation to deliver high quality and ensure repeatable consistency in the manufacturing process.

Rapid product development and rapid prototyping - what’s the difference?

Rapid prototyping refers to a group of techniques that enable fast fabrication of aesthetic and functional models of parts and assemblies. It allows engineers and designers to utilize CAD files to quickly create prototypes, and then modify them based on real-world feedback and testing.

The term ‘rapid prototyping’ has become synonymous with 3D printing. Beginning in the mid 1980’s, companies began using CAD to engineer their parts. Once the designs were digital, it enabled new subtractive methods, such as CNC machining, but also an entirely new capability with additive manufacturing. Over the years, the technology has vastly improved and recently the quality, speed and economics of 3D printing have reached a tipping point.

Rapid product development is an outcome of rapid prototyping and rapid manufacturing. Using the complete technology stack, companies can more quickly and efficiently innovate with designs and prototypes. With the advances in additive manufacturing, they can also produce end use parts. But if the strategy is to utilize a traditional method like injection molding, they can incorporate rapid tooling to create molds, further prototyping and test production. This allows companies to continually improve products before committing to mass production.

Benefits of rapid manufacturing

With rapid manufacturing, and specifically with 3D printing, speed isn’t the only advantage. Since additive manufacturing builds parts layer-by-layer, it consumes less material. Because the process is digital, and typically involves fewer production operations, it reduces the need for human labor. The digital workflow also eliminates much of the startup cost associated with other technologies, enabling customization and personalization at scale. These benefits are highly valuable to startups and lean organizations who can’t or would rather not invest capital in traditional manufacturing, large-scale inventory, or the eventual scrap as part designs continue to improve.

Practicing rapid product development and pioneering rapid manufacturing

GM automotive parts

General Motors has produced a variety of final parts using HP Multi Jet Fusion (MJF) 3D printing technology. Recently, for example, they used the solution to manufacture closeout seals for the spoilers of some of their most popular SUV’s. Working with HP and GKN Forecast 3D, they were able to streamline their additive manufacturing process, which enabled them to produce and finish 60,000 parts over the span of five weeks. Using conventional processes, the parts would have taken significantly longer and delayed production. In contrast, 3D printing allowed them to accelerate the scheduling of 30,000 vehicles.

Why was there a rush on the parts? GM engineers Adam Campbell and Christine Bardsley explained that in 2021, as GM was preparing its production line for the new 2022 models, an engineering change was made. The decision required a new part, which is very atypical, so late in the automotive product development process.

Instead of using traditional processes, which would have delayed customer deliveries, GM turned to the experts at its Additive Industrialization Center. Their additive manufacturing team recommended HP MJF, and working collaboratively, they were able to design and produce 3D printed closeout seals that are both aesthetically and functionally comparable to injection molded parts.

With rapid prototyping, the engineers at GM quickly designed the new part and conducted wind tunnel testing to ensure the part met aerodynamic specifications. Then they enlisted the support of GKN Forecast 3D to accelerate the finishing process. Within a few days, GKN Forecast 3D identified, tested and validated a new drying protocol that reduced the time it would have taken to surface finish the parts by 60%. With the time saved, the teams were able to accelerate their production schedule, saving GM time and cost, while eliminating the risk of production delays.

Read the full article about this rapid manufacturing use case to learn more about GM’s experience and future plans for additive manufacturing.

L’Oréal – flexible production lines

L’Oréal offers a full line of skincare and other beauty products and sells them through retail outlets globally. Like many luxury brands, they are very focused on packaging and its appeal to consumers. Their packaging styles change based on marketing and consumer preference. These packaging design changes create new challenges for L’Oréal’s manufacturing teams, as their filling machines must adapt to various bottle sizes and shapes.

To account for the different designs, L’Oréal uses a puck system to hold each bottle in place as it moves along their filling and assembly lines. When a new product is planned, they utilize rapid prototyping to produce new pucks. The prototypes are used to confirm that the puck will work with the package’s design and tooling used along the production line. They iterate the design until they confirm it meets their standards for performance and quality.

Data courtesy1

L’Oréal’s engineers also employ special software that uses biometrics and artificial intelligence to optimize the pucks for additive manufacturing. Once the puck designs are finalized, they are produced using HP MJF. Using this solution, they have been able to reduce the cost of pucks by 33% and the turn time by 66%. In addition, they are able to utilize the customization capabilities of 3D printing to create adjustable pucks that enable a more flexible production line. This allows L’Oréal to convey, fill, and label their products with greater agility.

Watch a video about the full rapid product development case study to learn more about how L’Oréal is utilizing HP MJF and HP’s global production network to create a more efficient and resilient supply chain.

How can you embrace rapid manufacturing?

Contact an HP 3D printing expert to learn how you can streamline your manufacturing processes with in-house 3D printing, or read about how a 3D printing service can help your business.

Want to continue learning?

Related article

Next article

Related content

Footnotes and disclaimers

- Data courtesy of L´Oréal.