Accelerate innovative

designs and products

Efficiently 3D print

metal parts at scale

Deliver top quality

3D printed metal parts

from a trusted global

industry leader

Scale production with HP’s

flexible offering

Revolutionize metal 3D printing with scalable platform configurations designed to grow with you, from development to mass production

HP Metal Jet S100D Configuration

Access and explore HP’s Metal Jet technology with a scalable, cost-efficient entry-level configuration to support material and part development activities.

Discover the different configurations and gain detailed insights into their specifications and intended usage.

HP Metal Jet S100P Configuration

Scale your capacity and produce quality metal 3D parts with a cost-efficient, scalable and reliable configuration that combines HP Metal Jet and compatible 3rd party optional solutions.

Discover the different configurations and gain detailed insights into their specifications and intended usage.

HP Metal Jet S100 Configuration

Achieve mass production with a complete configuration and efficiently produce high-quality 3D metal parts at scale.

Discover the different configurations and gain detailed insights into their specifications and intended usage.

Overcoming key challenges in metal 3D printing

Overcoming key challenges in metal 3D printing

Get operational efficiency and maximum system uptime with a complete set of solutions, materials, and services for your metal 3D printer.

Software

Software

HP Digital Production Suite provides the control and analytics required to scale additive manufacturing for a complete supply chain solution.

Materials

Materials

Three powder classifications available offering a perfect balance of fully tested parameters, qualified performance, and system compatibility.

Data courtesy9

Services

Services

HP Digital Production Services provide your business with a comprehensive suite of onboarding, maintenance, and professional services to help you achieve the most value with HP Metal Jet technology.

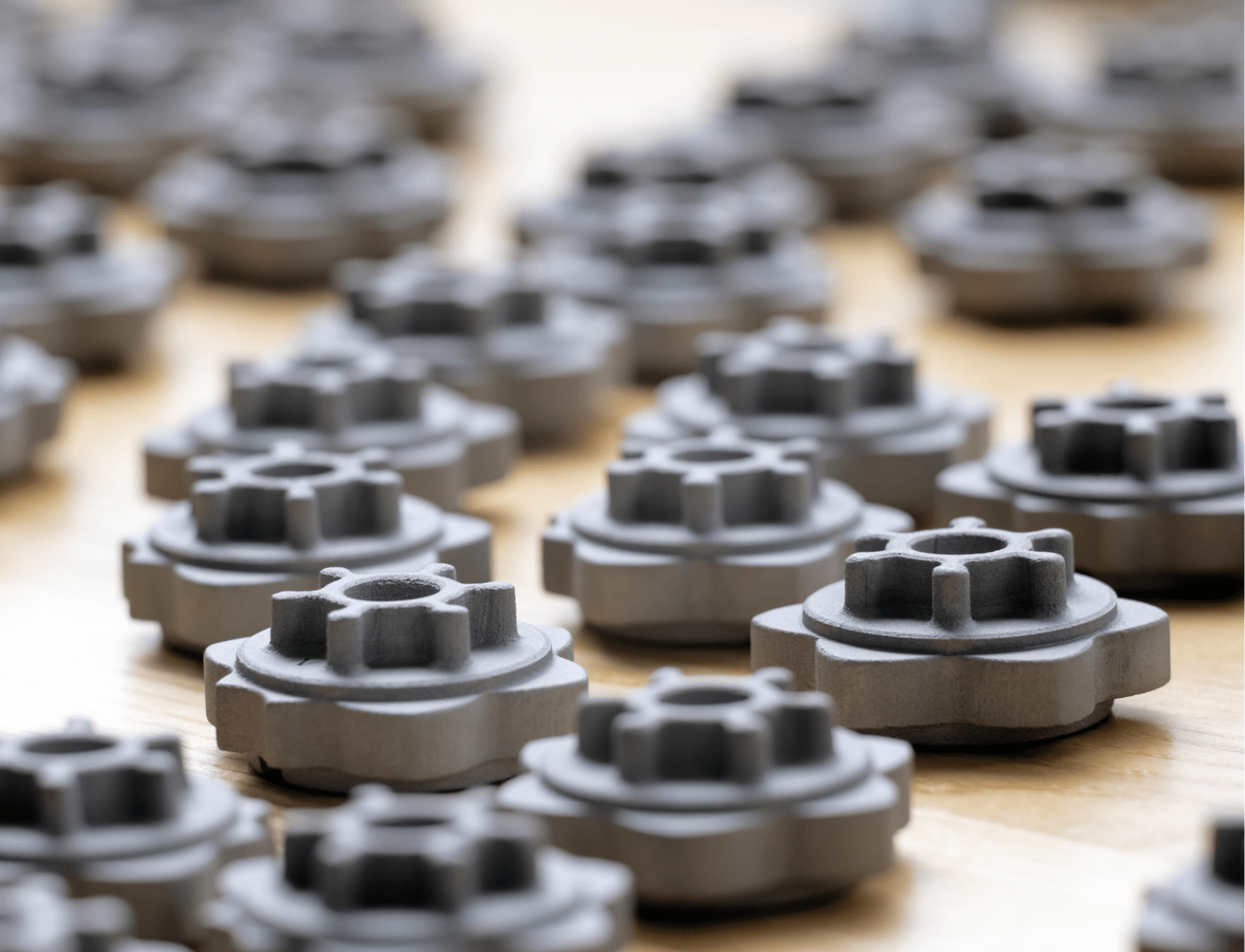

Explore new metal 3D printing applications

3D printing metal parts can help you eliminate the design constraints of analog technologies and produce innovative applications that you can mass customize and quickly deliver to market.

Consumer goods metal 3D printing applications

Automotive metal 3D printing applications

Industrial metal 3D printing applications

Hydraulics metal 3D printing applications

Leverage Binder Jetting technology and HP's expertise in additive manufacturing

Why metal 3D printing?

- Innovative designs enabled for lightweight or consolidated parts, performance improvements and customization

- Improved efficiencies and economics

Why binder jetting?

- Higher productivity from layer by layer process; less post-processing and no support removal required

- Cost efficient by using metal powders from established global powder suppliers

Why HP Metal Jet 3D printing?

- HP Thermal Inkjet printhead delivers economics and part quality (surface finish and accuracy)

- Leverages IP from HP Latex and uses minimum binder agent allowing for thicker and larger mass parts

Interested?

Discover more about metal 3D printing with HP

Contact us

Connect with an HP metal 3D printing expert

Fill in the form to start the conversation

Join the webinars

Join these sessions designed to educate, inspire, and empower professionals in metal 3D printing. Gain valuable insights from HP 3D printing experts, share knowledge, and unlock the full potential of metal additive manufacturing.

Order your metal 3D parts

Experience the benefits of HP Metal Jet technology before investing in-house—order your metal 3D parts from trusted industry leaders.

FAQs about metal 3D printing:

1. How does HP Metal Jet technology work?

The HP Metal Jet printer is a cutting-edge 3D printing technology designed for production of high-quality metal parts.

This printer utilizes a binder jetting process, where a liquid binding agent is selectively deposited onto a powder bed layer by layer to create a solid part. The process begins with a detachable build unit containing the powder bed and powder supplies, which is rolled into the HP Metal Jet printer for part production. The printer's high-speed printheads deposit the binding agent onto the metal powder, creating a green part that is later cured and sintered to achieve its final properties. This method allows to produce complex geometries and fine details that are difficult to achieve with traditional manufacturing techniques.

The printer's high throughput and scalability make it ideal for industrial, consumer goods, automotive and medical applications, enabling businesses to efficiently produce large volumes of metal parts with consistent quality.

Additionally, the HP Metal Jet S100 platform offers flexibility in production scales, allowing users to transition seamlessly from low-to-mid volumes to full-scale manufacturing without compromising quality.

2. How much is HP Metal Jet?

The cost of the HP Metal Jet 3D printer can vary depending on the specific configuration and production needs. Starting at approximately $550k, the HP Metal Jet S100 platform offers different configurations designed to meet various production scales, from development to low-to-mid volumes to full-scale manufacturing. For detailed pricing information and to get a quote tailored to your specific needs, it is recommended to contact an HP 3D Print expert directly.

3. What is the build volume?

The build volume of the HP Metal Jet varies depending on the selected configuration. The HP Metal Jet S100 platform offers different configurations to meet various production needs. Here are the details:

The HP Metal Jet S100 configuration is designed for mass production and has an effective build volume of 430 x 309 x 170 mm

The HP Metal Jet S100P configuration is designed for production and has an effective build volume of 430 x 309 x 100 mm

The HP Metal Jet S100D configuration, which is a cost-efficient entry-level option utilizing in-printer curing has a build volume of 430 x 309 x 40 mm

4. What materials can be used with HP Metal Jet?

The HP Metal Jet 3D printer is compatible with a variety of metal materials, each offering unique properties suitable for different applications. The primary materials used with the HP Metal Jet include stainless steels such as SS 316L and SS 17-4PH. SS 316L is known for its extreme resistance to corrosion and high temperatures, making it ideal for industries like automotive, aerospace, medical, jewelry, and oil/chemical. On the other hand, SS 17-4PH is valued for its high strength, wear resistance, and mechanical properties, which can be tailored through heat treatment. This material is commonly used in the medical, aerospace, marine, food processing, and automotive industries.

In addition to these certified materials, the HP Metal Jet also supports qualified and compatible materials from HP-approved suppliers. These include highly spherical metal powders such as other stainless steels, high-speed tool steels and nickel-based superalloys, which are suitable for a variety of end-use applications.

The versatility of the HP Metal Jet platform allows users to explore diverse applications while maintaining high standards of performance and reliability.

For more detailed information on the specific materials and their properties, you can refer to the HP Metal Jet materials page.

5. What are the advantages of HP Metal Jet over traditional manufacturing methods?

HP Metal Jet offers design freedom, the ability to produce complex geometries, and the potential for mass customization. It also reduces the need for tooling and can accelerate production timelines.

6. What industries benefit most from HP Metal Jet?

Industries such as industrial manufacturing, consumer goods, automotive and medical can benefit significantly from the capabilities of HP Metal Jet.

7. How can I get a part printed?

Visit HP Metal Jet Production service to order you parts from trusted industry leaders.

Disclaimers

- Not available in China

- Eg. Sinterzone furnace (available in EMEA region and China) or MUT and Carbolite Gero furnaces (available in AMS and EMEA region)

- Eg. Elnik Furnace

- Data courtesy of GKN Metallurgy

- Data courtesy of Schneider Electric

- Data courtesy of: Watch application from Legor and Amano+, fuel bypass manifold from John Deere and filters from Schneider Electric

- A single, one-year license to Autodesk Fusion software is included with the purchase of a HP MJF or a HP Metal Jet printer. Access to and use of the Autodesk Fusion software is bound by the terms and conditions of the Autodesk Fusion license. HP will provide a registration link to customers with a qualifying purchase to register with Autodesk to activate the Fusion license. Customers have 90-days to register for the Autodesk Fusion license upon receipt of the link. Bundle only available in United States, Italy, Spain, Germany, France, UK, Ireland, Japan, Canada, Switzerland, Sweden, Belgium, Netherlands, Luxemburg, Czech Republic, Slovakia, Poland.

- Data courtesy of Autodesk

- Data courtesy of Endeavour 3D

- Data courtesy of Cobra Golf

- Data courtesy of Legor

- Data courtesy of Volkswagen

- Data courtesy of Domin

- Data courtesy of John Deere

- Meets ASTM and MPIF standards for stainless steel