Overview of Construction Layout Robots

The ability of construction layout robots to accurately lay out MEP/FP systems is transforming mechanical engineering operations. These and other emerging technologies for installing fire protection systems on construction projects provide an efficient, automated workflow that accommodates other areas of the trade and reduces clashes between the various specializations working on the development.

According to a study by McKinsey, technology investment among construction firms has doubled in the past decade1. A significant focus of this new investment is on solutions like construction layout robots, which optimize workflows and drive profitability.

Mechanical contractors play a crucial role in this innovation, as they've quickly adopted the technology to gain a competitive edge. Contractors who use these robots benefit from enhanced reliability, expertise, and industry leadership. In so doing, they're able to ensure sustained growth in a rapidly evolving marketplace.

Importance of Precise Layouts for Mechanical Engineers & Contractors Working on Construction Projects

One of the reasons mechanical contractors are adopting this technology so widely is because of the importance of precise layouts for construction projects.

Ensuring Accurate Installations

A precise layout is important in all areas of mechanical engineering. But it takes on special importance for vital installations like fire protection systems. The safety of a building's inhabitants depends on the proper positioning of components such as pipes and sprinklers. If not laid out correctly, the components lose effectiveness and might not comply with safety regulations.

When even minor deviations can compromise safety, contractors should take every measure possible to improve the precision of their work. In addition to safety issues, the reinstallation required to fix a poorly aligned part costs contractors time and money, potentially delaying the product and angering the client.

Address Challenges with Traditional Layout Methods

Tools that enhance the precision of a layout are designed to address the challenges associated with traditional layout methods. Reliance on manual measurements, for example, is highly prone to inaccuracies. The deviations caused by these inaccuracies can affect the functionality and safety of installations like fire protection systems. This degradation of project quality leads many contractors to search out construction site fire protection system installation solutions that provide the accuracy they need.

Meeting Regulatory Standards and Client Expectations

A mechanical engineering project that doesn't meet regulatory standards and client expectations can damage the reputation of the company and potentially put it out of business. But projects that comply with building codes and industry regulations reduce the risk of fire-related incidents and liabilities.

To comply with these standards, mechanical engineers must stay updated on evolving regulations. This is complicated because these regulations can vary by location, building type, and occupancy. Further complicating the issue is the requirement for coordination between multiple project stakeholders. Emerging technologies for installing fire protection systems on construction projects can make this process easier.

Role of Layout Robots in Mechanical Engineering for Construction Projects

Robotics in construction have a distinct role in enabling successful projects. This role can be greatly enhanced when combined with other emerging technologies for installing fire protection systems on construction projects.

Overview of Construction Layout Robots

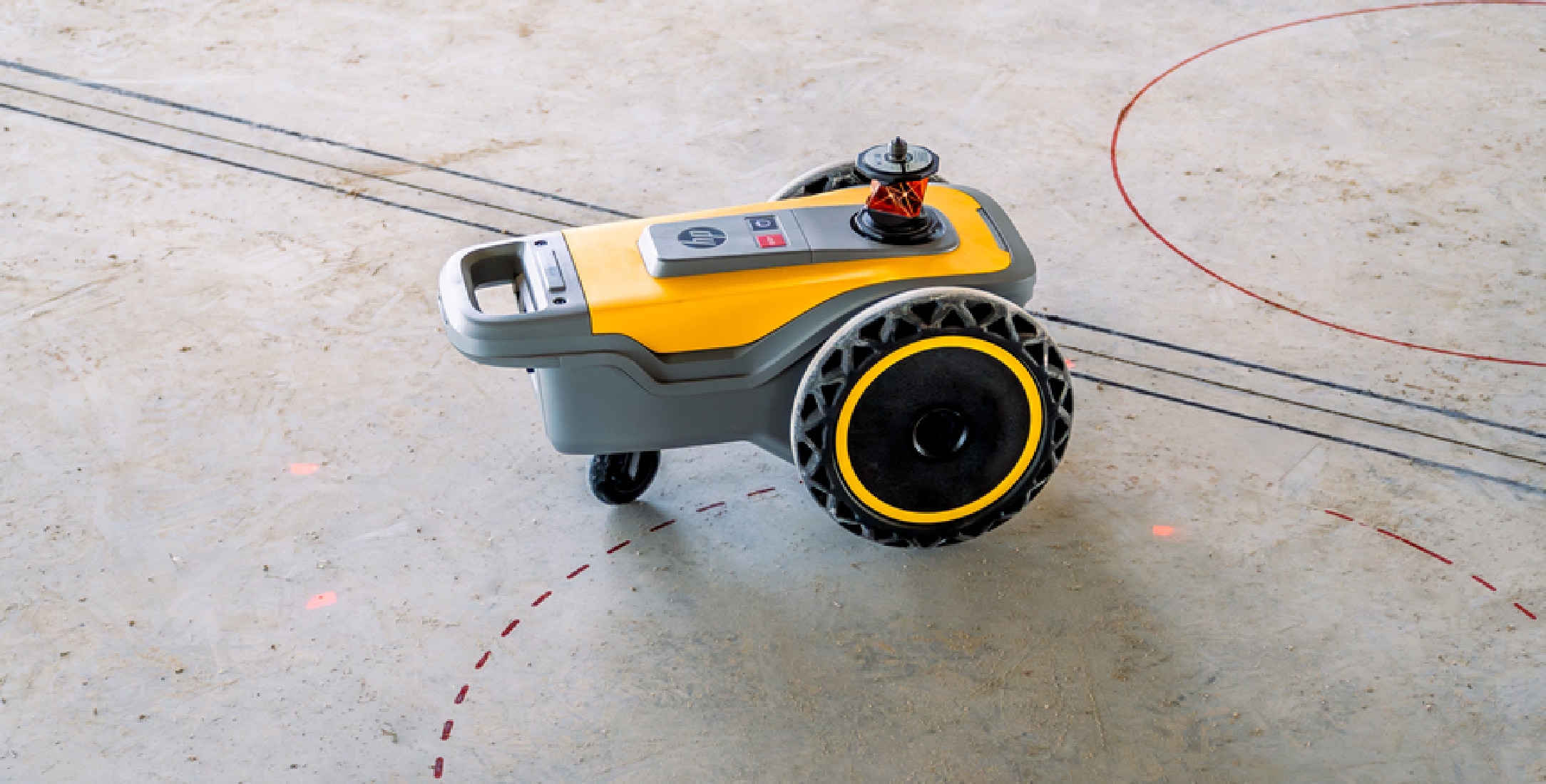

Construction layout tools are one of the emerging technologies that are changing the game in modern construction and mechanical engineering. These robots, such as HP SitePrint, operate autonomously, laying out a work site with precision and efficiency. Designed to be as versatile as possible, these devices are useful across multiple construction disciplines, from mechanical to electrical engineering.

HP SitePrint leverages advanced technologies to bring revolutionary changes to layout processes, particularly for MEP systems. These robots reduce time spent on clashes with other trades by ensuring a precise layout that meets the needs of every stakeholder involved in a project.

To maximize productivity, HP SitePrint robots also integrate seamlessly with existing workflows and current layout tools, ensuring minimal friction in the adoption process. They can further streamline processes by transferring on-site knowledge from the digital model in the form of text or assembly instructions printed alongside the layout.

Applications in Fire Protection System Installations

Construction layout robots are particularly transformative in the installation of fire protection systems. When used as part of a construction site fire protection system installation solution, these tools achieve greater precision and safety. Their advanced capabilities ensure fire protection systems are installed accurately, minimizing risks and ensuring optimal performance. They are also compatible with Robotic Total Stations, making it easy to integrate them into existing workflows for sprinkler placement and pipe routing.

Integration With Emerging Technologies

The integration of construction layout robots with other emerging technologies for installing fire protection systems on construction projects enhances project efficiency and effectiveness. These technologies combine in a synergistic way that makes the whole greater than the sum of its parts. For example, construction layouts can be integrated with AI-driven scheduling software, and prefabrication technologies reduce costs associated with the installation of fire protection systems by streamlining the process.

The synergy between these technologies can be enhanced when technology providers and mechanical contractors collaborate to develop customized solutions to address specific challenges. These technology-driven approaches showcase the innovative potential in the construction industry. Contractors who embrace these new approaches will complete projects more efficiently and effectively.

Future Outlook and Considerations

These new emerging technologies for installing fire protection systems on construction projects remain in their early stages. In the future, we can expect further refinements in efficiency that streamline workflows even more.

Continued Advancements in Technology

Technology companies continue to work on advancing their offerings in the construction industry. These technologies are currently in their early stages, making it hard to predict the future. Some exciting possibilities include:

- The use of augmented reality (AR) to provide real-time visualization of layouts for even greater accuracy

- The deployment of drones to conduct comprehensive site assessments for even more accurate layout planning

- IoT connectivity to bring greater data sharing between devices to further increase synergy and optimize workflow

- Machine learning algorithms to predict potential layout issues in advance and allow for proactive adjustments

Implications for the Construction Industry

The field of mechanical engineering is already changing with the introduction of emerging technologies for installing fire protection systems on construction projects. As they continue to evolve, we'll see a greater shift in workforce dynamics as workers adapt to new technology-driven roles. Mechanical contractors who adopt these technologies early on can position themselves to be leaders in innovation and efficiency, setting the benchmark for the future of the industry.

But challenges to adoption remain. Whenever new technology enters the workplace, it faces resistance or skepticism that needs addressing. These problems can be overcome with continuous training, a thorough demonstration of the benefits, and a culture of innovation.

To learn more about the HP SitePrint Robot, contact us today by tapping on the top corner of your screen to reach out.

Selected for you

The benefits of site layout robots for both large and small-scale construction projects

Digitalization in Construction: How to Embrace Emerging Technology Trends

Understanding How SitePrint Robots Eliminate Guesswork When Interpreting Architectural Proposals

Contact us

Talk with an expert

Contact us to get pricing information and to take par in the HP SitePrint Early Access Program.

Stay informed

Sign up to stay informed on the evolution of HP SitePrint and an entire industry.

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2025 HP Development Company, L.P. The information contained herein is subject to change without notice.