The new math of label printing

HP Indigo V12 Digital Press is the first press to utilize the new industry-altering LEPx technology. A narrow-web label press, printing at 120 linear meters per min with all the capabilities of HP Indigo’s technology for label production.

Outstanding earning power

Use powerful V12 throughput to replace multiple flexo presses and their overhead.

Rooted in an industry winning formula

Cutting-edge LEPx technology elevates your operation with breakthrough efficiencies built on proven HP Indigo capabilities.

Profitability meets sustainability

Producing most of your job basket on an HP Indigo digital press fleet is cost effective and enables brands to meet your sustainability goals.

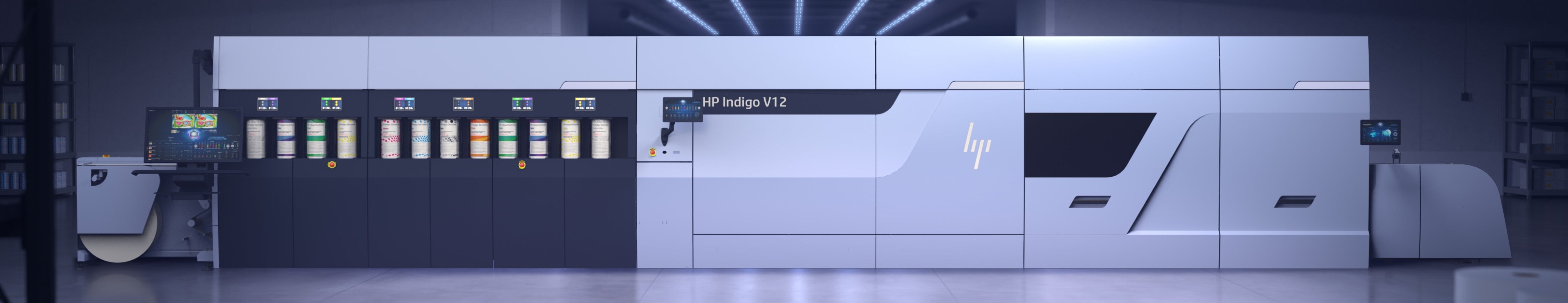

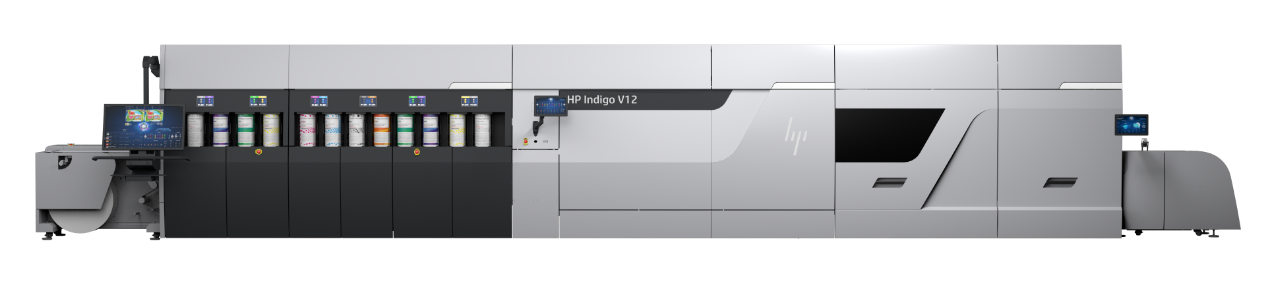

The HP Indigo V12 Digital Press

The new HP Indigo V12 is the first press to utilize the new LEPx technology. A narrow-web label press that prints at 120Lm/min.

The HP Indigo V12 Digital Press

The new HP Indigo V12 is the first press to utilize the new LEPx technology. A narrow-web label press that prints at 120Lm/min.

Optional continuous unwinding for nonstop printing mode

Print on almost any media

Two color stations per imaging engine for endless color combinations

Designed to maximize productivity with a long lifespan

Allowing printing at 120 meter per minute with up to six different inks, and 60 meters per minute with seven to twelve inks

Delivering HD quality at 1600 dpi

Print at 120 Linear meter per min – comparable to analog print speeds.

12 ink stations with one automated ink replacement revolver per station.

HP Indigo color gamut enables 97% of PANTONE colors

New UI station with views for print queue, Inspection and press monitor

Optional continuous unwind for nonstop printing mode

End-to-end solutions

Print Care

Manage press operations with on-press self-guided resolution and automated solutions.

Predictive Press Care

Provides innovative technology that helps you predict potential issues before they occur. Our experts will contact you with issue resolution and corrective actions, before production is impacted.

HP PrintOS Production Pro server for Indigo Labels & Packaging

The most advanced Labels & Packaging Digital Front End (DFE) we have ever created, supporting even the most challenging workflows.

Drive efficient and profitable production and create applications that will stand-out on the shelf, using partner solutions for HP Indigo labels and packaging presses. The combination of HP’s leading technology and workflow software with finishing partners’ solutions enable print service providers to produce profitable applications such as labels, in-mold labels, shrink sleeves, flexible packaging, and folding cartons.

Turn HP Indigo ElectroInks into your competitive advantage.

HP xRServices offers simplified support, instant troubleshooting, and real-time collaboration with mixed reality customer support for a next generation of printers

Increased press and system availability

Win additional production availability time with faster diagnosis and resolution, mixed reality visual guidance and increased self-sufficiency. Keep your print operations running in top form and take on jobs with total confidence.

Immediate access to experts

HP's mixed reality services deliver immediate access to HP experts and empower effective collaboration to speed up resolution. Our virtual experts guide you every step the way so that you can quickly get your operations back to optimal performance.

Faster onboarding

Accelerate onboarding and upskilling with best-in-class access to remote guidance and simulated on-the-job training. Equip your operations workforce with the agility to quickly learn complex tasks and collaborate in real time, from anywhere.

Discover more about HP Indigo Digital Presses

HP Indigo Labels

HP Indigo’s latest label portfolio is pushing the limits of label production further than ever before, creating the label factory of the future.

Sustainability

Bring your business into the circular economy today and prepare to excel in the new way that print will be done.

Disclaimers

- Highest production speeds based on press specification comparison of major digital printing competitors as of September 2022.

- Based on internal HP analysis July 2022. Flexo set-up time is roughly 1 hour, compared to 10-15 minutes using HP Indigo. Set-up waste using flexo presses can be anywhere from 200-500 meters versus tens of meters with digital.

- Compared to major digital printing competitors as of November 2022.

- The digital industry’s widest range of inks and largest range of substrates compared to major digital printing competitors as of November 2022, based on internal HP analysis.

- Selected HP Indigo ElectroInks were tested for compostability against leading standards, and can be used, under certain limitations, as an ink for printing compostable packages (Industrial and Home Composting). For details on approved inks and allowed limits, please contact the HP Indigo team for more information.

- Food products and packaging are a highly regulated sector, with varying requirements depending on where they are placed on the market. In relation to inks, compliance depends primarily on the potential for ink substances to migrate through the specific packaging materials into food as well as the intended use case for the packaging. Converters must perform their own assessment to ensure compliance of the final packaging they produce and ensure that the printing is performed in accordance with Good Manufacturing Practices. HP Indigo ElectroInk can be used to produce food packaging that complies with: FDA, Title 21 of the Code of Federal Regulations for indirect food contact; Swiss Ordinance on Materials and Articles in Contact with Food, RS 817.023.21; European Printing Inks Association (EuPIA) Guidelines on Printing Inks applied to Food Contact Materials, version April 2020; Council of Europe Resolution ResAP (2005/2) for indirect food contact; Nestlé Guidance Note on Packaging Inks, exclusion lists for indirect food contact; German Food Law and Article 3 of the EU framework regulation 1935/2004, for non-food contact.