Achieve operational efficiency for high-volume production with a robust digital web-fed platform for paper-based packaging.

Efficient and economical paper-based packaging production

Streamline processes, improve productivity, and help reduce costs for digital single-face lamination, corrugation, and folding carton applications.

Offset quality with six-color printing

Meet customer demand for offset image quality with six-color printing and achieve consistent quality in fewer steps.

Fuel your success beyond the press

Quickly ramp up digital production with HP as a trusted partner and E2E solutions that integrate into your current environment.

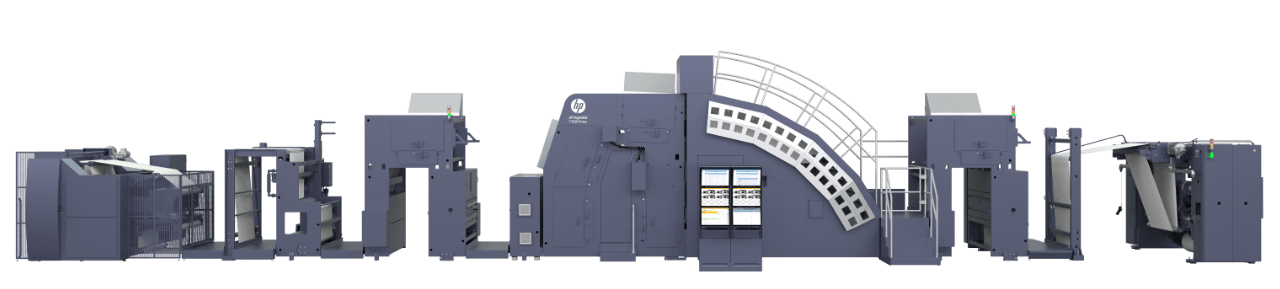

HP PageWide T700i Press

Increase manufacturing productivity and optimize your print quality with HP’s technology innovations.

The press is equipped with a fully automated match speed splicer. The Autosplice Unwinder is capable of unwinding paper ranging from 80-250 gsm with a maximum caliper of 16 points. Additional options for unwinding are available for heavier paper weights.

The Pre-Coater applies HP Priming Agent to the paper as a flood coat. HP’s Priming Agent is an aqueous solution that ensures optimal print quality across a range of paper types.

The HP PageWide T700i Press prints roll-to-roll or roll-to-sheet at speeds up to 300 m (1000 ft) per minute on 1.7m (67in) wide paper. The curved arch design provides tight control of the paper tension for accurate printing while maintaining a very small printhead-to-paper spacing to ensure clean, sharp text and images.

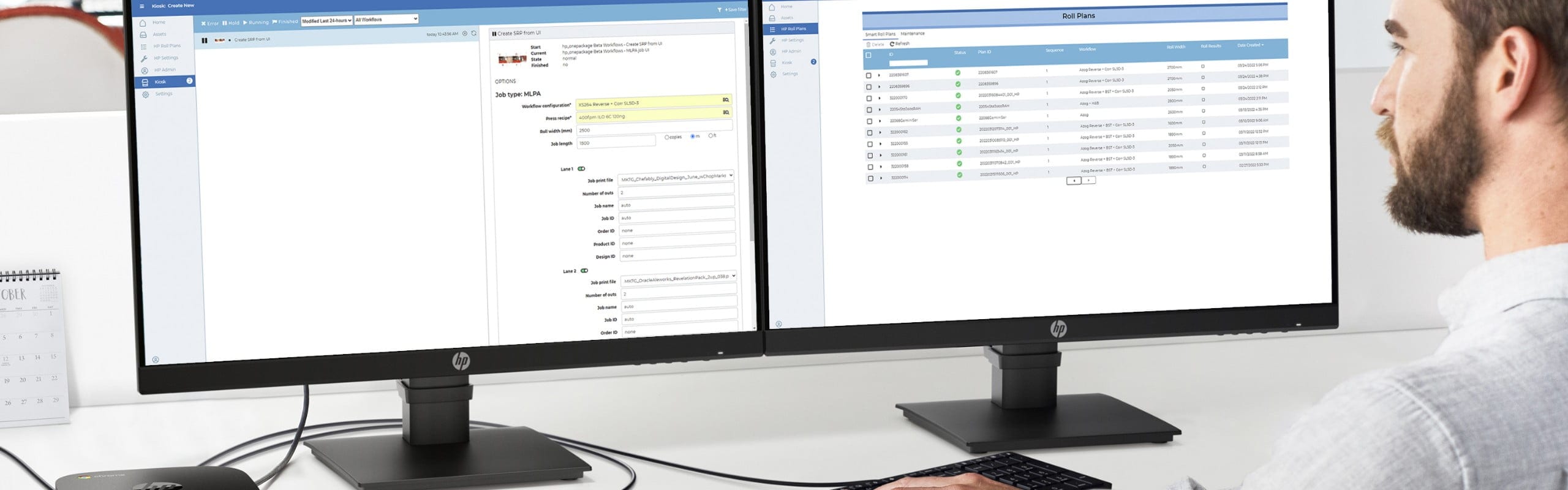

The HP SmartStream Production Elite Print Server is a highly scalable server-based Digital Front End that rasterizes incoming artwork files and delivers data to the press in real time.

After printing, the paper passes through several high-intensity dryer sections that use a combination of infrared light and forced air to enable the ink to dry on the paper.

The Inline Process Control System uses high-speed cameras to capture samples of printed output to monitor nozzle health and ensure top inkjet print quality.

OPV is applied as either an aqueous flood coat, aqueous spot coat, or aqueous/UV spot coat, then dried or cured using an integrated dryer. OPV protects the printed surface, offers performance properties for a variety of end-use applications, and enhances visual appearance.

Throughout priming, printing, and varnishing, the paper goes through several cycles of wetting and drying. The Moisturizer replaces any moisture that is lost during these drying processes and helps to restore the paper to its original characteristics.

The Turret Rewinder couples with the Autosplice Unwinder to provide continuous press operation and fully automated reel changes. Additional options for rewinding and sheeting are available for a variety of applications.

End-to-end solutions

Digital web-fed printing

Web-fed printing enables high-quality production for single-face lamination, corrugation, and folding carton applications at high speeds with flexible cut-off lengths.

Thermal Inkjet

The thermal inkjet printheads on the T700i have 1200 nozzles per inch to help converters achieve offset quality, with sharp text and barcodes and smooth tone transitions.

HP A30 water-based inks are 100% free of UV-reactive chemistries

HP A30 water-based inks are 100% free of UV-reactive chemistries to meet brands’ packaging safety requirements for sensitive products with non-contact packaging.

Planning & Submission

Print Preparation & Prepress

Production & Conversion

Print beat

Gain visibility into press efficiency with real-time, data-driven insights to drive continuous improvement in print operations.

Knowledge zone

A searchable repository of technical, training, application, and marketing resources.

Media locator

Easily find papers in use on HP PageWide Packaging Presses to fit your business needs by searching according to the specific attributes required for the target product.

Business transformation services

Achieve confidence in digital production from launch by aligning converters business goals with the digital adoption journey and building one plan to meet production and OEE targets.

Digital Pack

Digital Pack, in partnership with HP, is the world’s leading digital print corrugated supplier network providing greater speed, efficiency, and agility to global brands.

Discover more about HP PageWide Presses for Corrugated Packaging

Technology

Grow your packaging portfolio with proven technology and true water-based inks that open the door to new possibilities.

Corrugated packaging applications

Expand into new applications to deliver more variety and more options with true water-based inks and offset quality.

PageWide Corrugated sustainable impact

Improve your sustainability offering to customers with a solution that reduces the environmental impact of printing.

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.